Having restored many of our own parts and projects over the years, we have felt the frustration of having to cart your project around between niche’ suppliers to get the finish required. From start to finish, the team at ACR offer every service that you could need for componentry repair, restoration, and refinishing. We offer and can customize the below services to suit:

With sustainability at the forefront of their services, the team are passionate about achieving the best restorations and refinishing possible. From automotive, powersports, aviation, and marine componentry, to household items and antiques, give us a call today to see how we can help you.

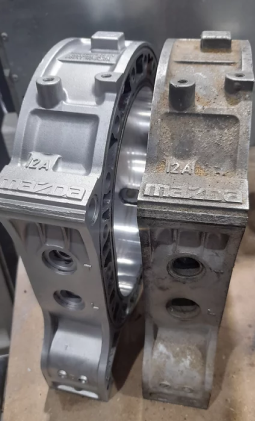

Before

Before

After

After

Our workshop facilities can repair buckles, cracks, or bent rims, carry complete colour changes, CNC Machine Face your Diamond cut rims, or tidy up blemishes on your rims to get them looking like new.

Our services include removing your tyres, checking your wheels are true and free from faults, then safely stripping your wheels, preparing them for powder coating, and powder coating them in a wide range of custom finishes. As an authorised applicator for Prismatic Powders - ACR Page, we offer a vast range of colours and options.

If you have a buckled or cracked wheel, we can repair it so you can keep moving.

We can repair your rim faces with our state-of-the-art Vertical Wheel Lathe to get your wheels looking like they have just come from the manufacturer.

Your wheels don't have to look damaged and untidy. We can repair your rims to get them looking great again.

For the high-quality finish with impeccable attention to detail, save yourself double handling time – come to the team that offer sandblasting and powder coating under the one roof. As an authorised applicator for Prismatic Powders - ACR Page we offer a huge range of options for colours & finishes.

Looking for a finish that provides not only protection but a finish that is more practical for everyday use? Choose powder coating. Baked onto the component and bonding the colour on a molecular level, powder coating is resistant to chipping, scratching, fading, and wearing - the colour and sheen will keep for years to come.

An economical finish for any metal part, the diverse range of colours and finishes is almost unlimited – giving you the result you imagined. From a metallic finish to a full matte or gloss finish, powder coating offers you the best value for money. The team at ACR will work with you to discuss your custom powder coating and paint requirements for any automotive, powersports, marine or aviation components. No job is too small!

The unique composition of our ceramic polymer coatings provides unrivalled thin film surface performance and aesthetic properties for automotive, powersport, marine, or aviation applications where you are seeking improved performance and looks.

ACR is a qualified and authorised applicator for Cerakote - ACR Page , we offer a wide range of colour and functional coating options.

Our High Temperature Coatings are ideal for componentry that requires a superior heat management system to provide faster gas flow velocity. Perfect for components within and around engines or areas such as exhaust headers/systems, intake manifolds, turbo housings, and brake callipers. Withstanding temperatures up to 980C, ACR high temperature specialty coatings allow for cooler, more efficient, and higher performing engines.

Piston coating reduces temperature, increases horsepower and torque, reduces, or eliminates detonation, and allows for higher compression ratios to be utilised.

By transferring heat away from a substrate faster than the substrate can, heat transfer coatings reduce exposure of coated parts to a constant hot-cool cycle, reducing the risk of metal parts weakening greatly.

Designed for components operating in high stress and heat environments to aid is high temperature lubrication. Ideal for piston skirts, valve stems or any surfaces that require protection from corrosion, wear, or friction.

ACR offer both gloss and matte clear finishes to maintain and protect the surface of your componentry and restoration projects. Ultra-Thin application allows for a clear coating to protect areas where exact tolerances are required.

Vapour blasting uses a combination of water, compressed air, detergents with specialist media combinations to clean and restore surfaces. Through this combination of water and specialist media used under pressure, the substrate is safe from heat, warping, or any damage.

It is safe on nearly all substrates, without the risk of the removal of surface material.

Vapour blasting offers an innovative and specialised surface treatment allowing a gentle process that cleans, and polishes components to a stunning revived satin finish.

Utilising various media combinations and depending on your desired finish, ACR can restore a multitude of surfaces on materials such as aluminium, magnesium, brass, copper, steel, stainless steel, cast iron, plastics, wood, and glass back to showroom condition.

Not only can we vapour blast your automotive, powersports, marine & aviation components and accessories, we can lovingly restore antiques using this technique. ACR offer a range of custom finishes and work closely alongside you to ensure your pride and joy stands out from the crowd.